Royal3D: a sustainable ship right out of the printer

The hull of a sloop, a workspace in the shape of an igloo or a kennel for his puppy. They roll right out of the printer at Royal3D in Merwe-Vierhaven, all made from recycled and reusable materials.

Fulko Roos is on a mission with Royal3D: printing to make the maritime sector more sustainable. “The items we are currently printing represent important intermediate steps. Soon we will be printing workboats, for example, for the boatmen in the Port of Rotterdam. Big plans, but we also have a big printer."

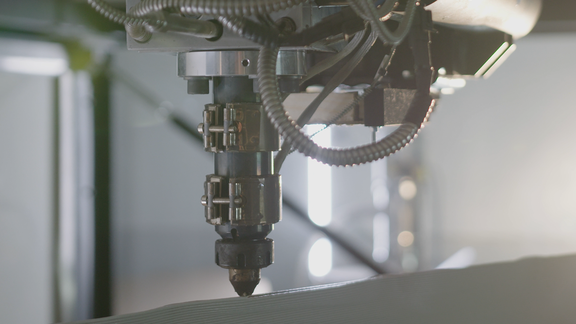

The printer for the sloops, a collaboration with duurzamesloepen.nl, is working overtime. Roos: "Printing the hull of a small sloop takes two days, a large one measuring eight metres takes a week. In the near future, we want to print around 40 small sloops and 80 large ones. That’s why we are in the process of purchasing a second printer." When Roos was able to buy a 3D printer four years ago, it seemed like a good opportunity.

"I saw a future in making prints on a large scale for the maritime industry. 3D printing sounds like the ultimate solution to major issues, but in fact it wasn’t straightforward. After all, there’s no such thing yet as a large affordable printer that immediately prints a product that you want, like a ready-made ship. With Royal3D we had to conduct a lot of research on how to optimally approach this challenge. I underestimated it somewhat, but it was a good lesson. Apart from the fact that 3D printing offers a lot of freedom of form - you can print almost any shape you want - it can also be difficult because you constantly have to look for suitable materials. But the major advantage is that you can constantly experiment with materials and how to make them stronger."

Revolution

Roos is determined to use 3D printing to revolutionise the maritime industry. "Of course, until recently, printing a ships was unthinkable. But technology is developing at a rapid pace. With our printer, we can now quickly and accurately print ships and parts that are strong enough. The 'base material' for the prints is plastic, and some of it comes from plastic waste. The advantage of printing is that there is less residual material, and the material can be recycled and reused. Currently, we are only printing pleasure boats until we can also print real, large ships. For example, for the boatmen or pilots here in the port, or for Rijkswaterstaat."

Countless possibilities

The possibilities for printing are countless, for example, in addition to sloops, Royal3D prints façade panels. Roos: "A lot of building work is required and there is a considerable need for greenery. You can effectively combine these elements in façade panels, in which you can incorporate vertical gardens. We also make transport packaging, such as cradles for transporting yachts. And the R-Iglo of course, an acoustic workspace that is easy to install in large, noisy rooms; the prototype is at RDM. We also printed an aquatic drone. You can equip them to carry out inspections of ships, banks or quays."

You can print anything

Other products or collaborations arise from the products Roos prints. "For example, the R-Iglo has led to cooperation with our neighbours opposite, Future Mobility Park, a test site for autonomous vehicles. We are printing a dome where their vehicles can stay dry while plugged in to recharge. We also cooperate with our other neighbours. They are very diverse and at first glance there is not much common ground. But after a while it turns out that there are some things you can support each other in. For example, borrowing a forklift truck or printing something. What's great is that something then takes root, from which an idea emerges that leads to something sustainable for the parties involved. You can print the craziest things. This sometimes results in fun items for ourselves. For example, we recently made a kennel for Slof, our Bernese Mountain Dog, who regularly comes to the office.”

From helmsman to entrepreneur

The fact that Royal3D is committed to the maritime sector is not entirely coincidental. Roos is originally from Amsterdam, where he attended nautical college. He then went on to study maritime engineering at TU Delft. "In between, I also sailed a lot, as a helmsman and as an engineer. Afterwards, I joined Smit Salvage as a project leader, working on salvaging shipwrecks and providing support in the event of maritime disasters."

In 2009, Roos started his own company: Royal Roos, which focuses on designing ships, maritime constructions and conversions and repairs. The business soon grew and Roos opened a branch in Ferrol, an important naval port on the Atlantic coast of Spain, where there are many qualified staff and customers. He also founded the company UniBallast, which focuses on ballast water management and develops sustainable systems that reduce ships' emissions and fuel consumption.

Big steps

Sustainability is the common thread in everything Roos undertakes. Roos: "We want to demonstrate that it can be done. There are many initiatives in the field of sustainability, but they also have consequences. Take electric vehicles, for example, which have quite an impact on the public space. Sometimes it seems like things don't make much sense, you take drastic steps for a minor effect. But they are needed to move forward. And much of the technology is still being developed. We are still working with Royal3D to optimise the process. Many materials still deform, which is why we still use expensive printing materials that don’t deform too much. We want to develop materials that do not deform and are also affordable. Of course, sometimes things do go wrong in the printing process. We put the misfits in the shredder to produce material that we can add to the printing material."

Landlord with vision

Royal3D has discovered a good partner in the Port of Rotterdam Authority. Roos: "Our vision fits well with the Port Authority’s long-term vision. We both strive for progress, in a sustainable manner. We are happy to be here, right by the water where we can develop and test. It is a great collaboration, for example we are now investigating the possibilities of making products and printing materials from plastic waste from the port."

Way of life

For Roos, sustainability and circularity are a way of life. "For example, the roofs of the office building and the warehouse in the Merwehaven are covered in solar panels. We generate 100 percent of our own renewable electricity with them." "My family and I own a two-hectare piece of land in Zeeland, from where we get wood for our wood-burning stove at home. And we also plant more trees. Everyone now believes that sustainable is the way to go. Partly because of Covid-19, people and companies are increasingly realising that it is nonsense to drag products from all over the world. We will produce more in Europe. In the event of major changes of this kind, the opportunities lie precisely with smaller SMEs, because they are flexible and decisive; they can respond quickly to developments. Small businesses are the future!”